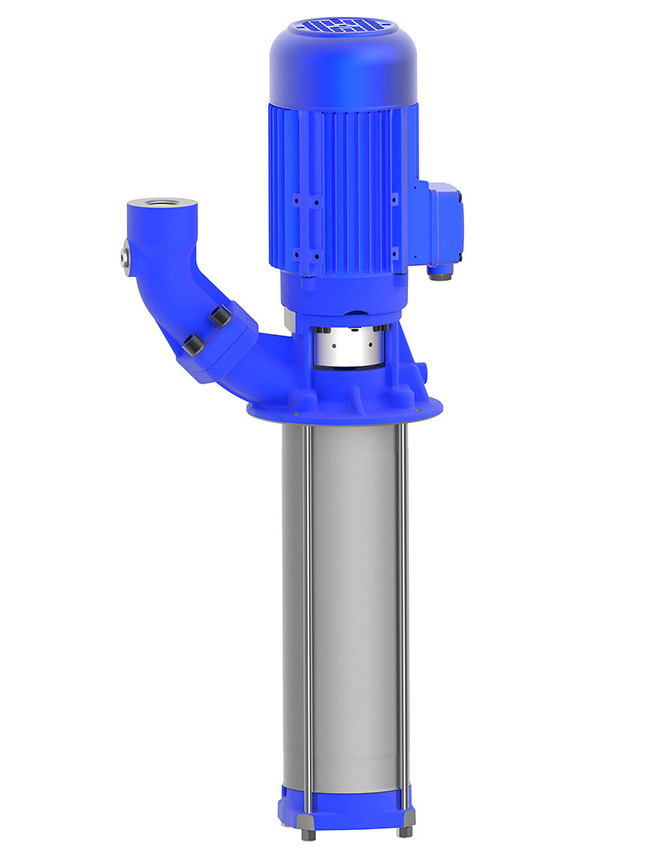

Immersion Pumps

(S)TH | STH

Immersion Pump

-

Easy mounting on top of the tank

-

Simple piping connection with optional SAE flange

-

Closed impellers provide optimal hydraulic efficiencies while minimizing power consumption

-

Pump performance curves can be regulated using an adapted frequency converter

-

Grinding version available

-

An even wider range of performance curves

| Item group | Pump type | Capacity |

Head |

|||||||

|

|

Immersion Pumps | 40 l/min | ...240 m | ||||||

|

|

Immersion Pumps | 74 l/min | ...270 m | ||||||

|

|

Immersion Pumps | 142 l/min | ...240 m | ||||||

|

|

Immersion Pumps | 234 l/min | ...250 m | ||||||

|

|

Immersion Pumps | 400 l/min | ...240 m | ||||||

|

|

Immersion Pumps | 485 l/min | ...255 m | ||||||

|

|

Immersion Pumps | 47 l/min | ...265 m | ||||||

|

|

Immersion Pumps | 87 l/min | ...260 m | ||||||

|

|

Immersion Pumps | 167 l/min | ...260 m | ||||||

|

|

Immersion Pumps | 284 l/min | ...250 m | ||||||

|

|

Immersion Pumps | 484 l/min | ...250 m | ||||||

|

|

Immersion Pumps | 568 l/min | ...240 m | ||||||

|

|

Immersion Pumps | 900 l/min | ...220 m | ||||||

|

|

Immersion Pumps | 1350 l/min | ...150 m | ||||||

|

|

Immersion Pumps | 1200 l/min | ...190 m | ||||||

|

|

Immersion Pumps | 1550 l/min | ...125 m |