Coolant pumps and digital systems

Pump solutions for a wide range of applications

Our product development focuses on cooling, temperature control or humidification of various processes in mechanical engineering. Our pumps are used in machine tools and filter systems for coolant supply, at high temperatures in the plastics industry or in the printing industry. Our products are used in many other applications, for example, dosing, plastics recycling, electromobility or renewable energies.

Machine tool industry

Pump solutions for machine supply, filtration or return pump stations

About the machine tool industry

Printing industry

Reliable recycling of humidification solution with plastic pumps

About the printing industry

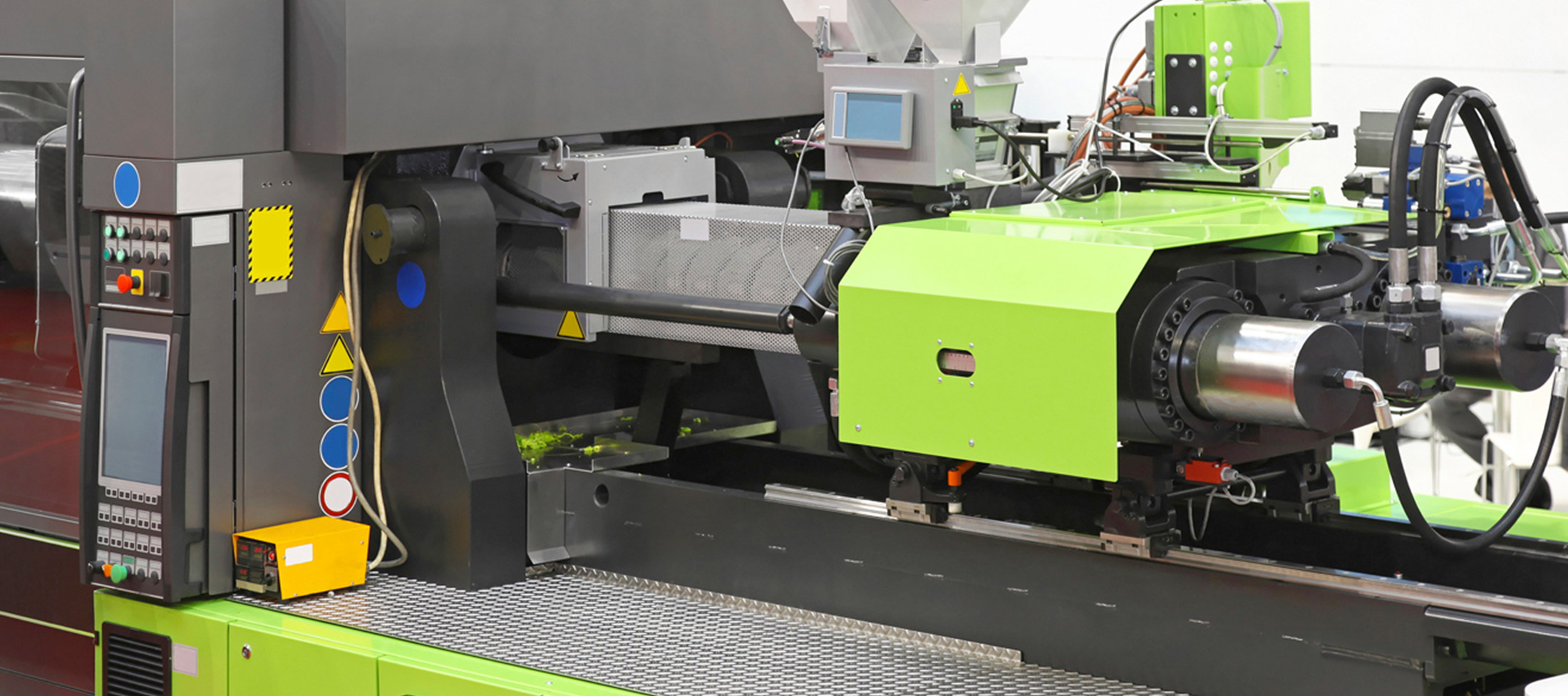

Plastic industry

Immersion pumps and small centrifugal pumps for temperature control units

About the plastics industry

Optical INDUSTRY

Plastic pumps and centrifugal pumps for the spectacle and precision optics industry

About the optical industry

INDUSTRIAL PARTS CLEANING

Stainless steel pumps and centrifugal pumps in cast iron for industrial cleaning systems.

To industrial parts cleaning

![[Translate to UK - english:] Stage Image](/fileadmin/user_upload/header_branchen_2200px.jpg)