Our product range

Pumps, motors and digital solutions for the industry

BRINKMANN PUMPS offers you intelligent pump solutions and innovative systems for industrial use. In addition to a complete range of coolant pumps based on centrifugal pumps or screw pumps, the product portfolio also includes drive motors as well as the digital pump control bplogic and the frequency converter FKO. In addition, our Advance service package offers comprehensive services.

Our pumps are typically applied in applications such as central filtration systems, pumpback stations, individual filtration systems, dampening systems, tempering systems and beverage cooling. In any case, we focus on customer-oriented pump technology which perfectly fulfills all requirements.

Machine tool coolant supply

Low Pressure Pumps

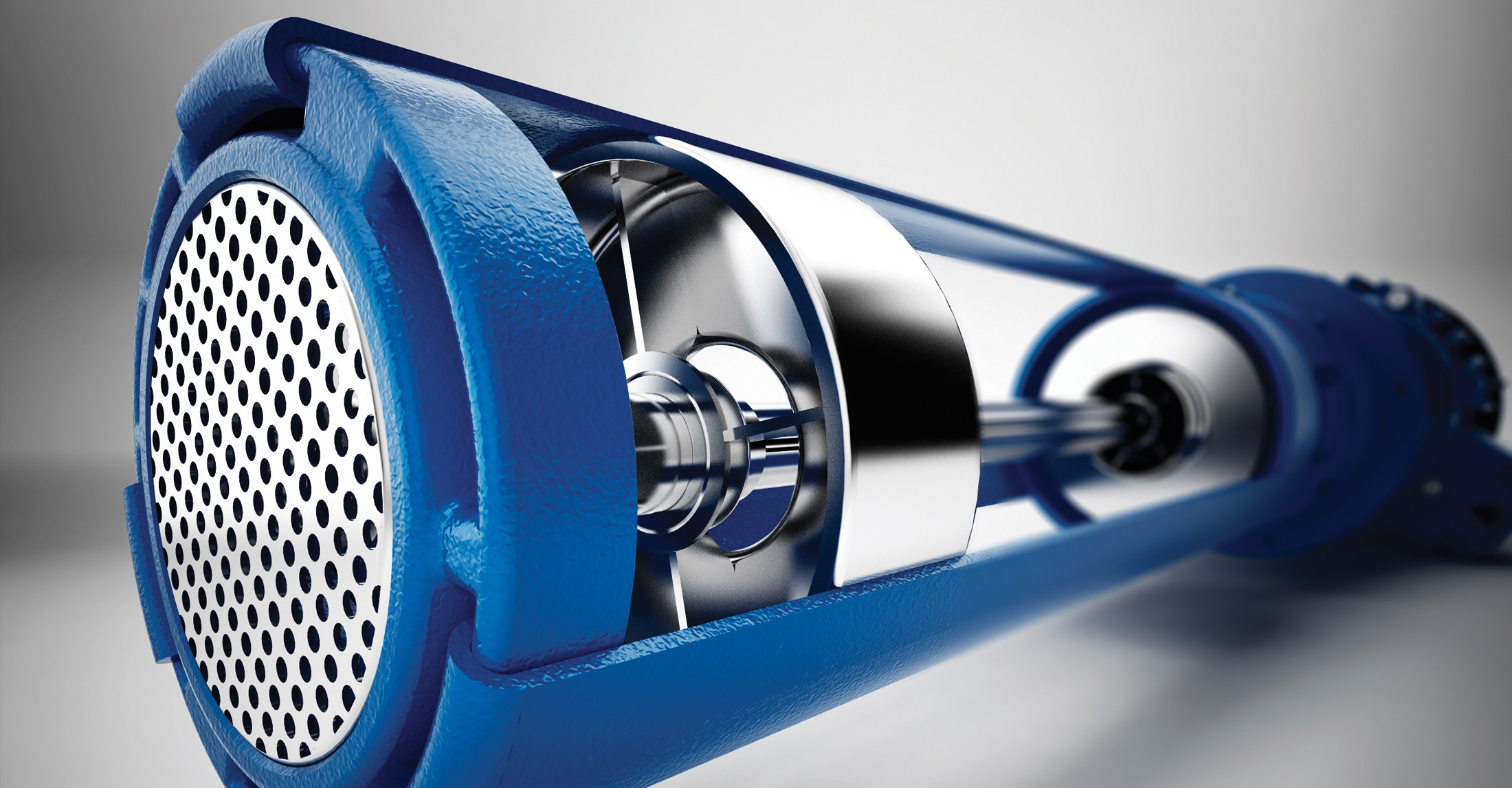

Wear resistant centrifugal pumps for rinsing, cooling, or backflushing filters or as single stage lift pump

- Immersion Pumps

TB | TA | TE | STE | STA | TVG | TVA - Quick Suctioning Immersion Pumps

TL | STL | TAL | SAL | TGL | SGL | SZG - End-Suction Pumps horizontal, vertical, self-priming

SBA | SBA-V | SBG | SBG-V | SBM

Chip handling

Lifting Pumps

Lifting pumps for return pump stations, cutter pumps for cutting and pumping chips or vortex free flow pumps

- Quick Suctioning Immersion Pumps

TFL | SFL | SAL | SGL - Horizontal End-Suction Pumps

SBF | SBF-V | SBA | SBG - Cutter Pumps

SFC | SXC | SPC | SGC | TVC | SBC - Free-flow Immersion Pumps

FT | FTA | SFT - Suction Pumps / Lifting Pumps

TAA | TAS | STS

Plastic Pumps /

Miniature Centrifugal Pumps

Special solutions for temperature control units and industrial water applications

- Plastic Immersion Pumps

KTF | KTB - Miniature Centrifugal Pumps / Suction Pumps

SB | KC - Miniature Centrifugal Pumps / Immersion Pumps

B | BMK | TB-M

Centrifugal pumps, screw spindle pumps, motors and controls

Send us your request for your special requirement

You cannot find a suitable product? Then use our online inquiry forms or call us directly. We will be happy to advise you.