2023

01.12.2023

Merry Christmas!

We would like to thank you for the exciting challenges, your trust and the friendly cooperation this year. We wish you and your family Happy Holidays and a good start into a successful and peaceful new year.

Our company will be closed for the Holiday Season: 23 December 2023 to 01 January 2024

Your BRINKMANN PUMPS Team

21.08.2023

EMO Invitation 2023

Coming soon! EMO 2023 – the world's leading trade fair for production technology – will start again in Hanover from 18 to 23 September 2023.

Be there live and experience our TEAM DIGITAL at our booth in hall 6, G32. Take the opportunity and have a look at our highlights:

- Live demo of our digital systems for pump monitoring and pump control

- Pumps for battery and fuel cells cooling in e-mobility applications

- Plastic pumps for use in cooling data centers, the optical industry and many other applications

- The perfect team for back pump stations: small cutter and lifting pumps for low flow rates

Get your free ticket now:

Our team looks forward to your visit and feedback on our new developments. We will be happy to discuss your ideas and answer your questions.

Your BRINKMANN PUMPS Team

08.02.2023

Ecodesign Directive 2009/125/EC, Regulation (EU) 2019/1781

According to EU Regulation 2019/1781 on the Ecodesign Directive 2009/125/EC, all single-phase motors ≥ 0.12 kW must comply with minimum efficiency class IE2 by July 1, 2023.

The implementation at BRINKMANN PUMPS takes place on time. Orders from March 1, 2023 will already be confirmed in the required version. Pumps/motors placed on the market by the manufacturer before July 1, 2023 can still be used, installed and resold after the deadline.

- All previous 0.12 kW – 0.4 kW motors will be replaced by a new generation of motors in efficiency class IE2. Motors with larger rated powers are no longer required. Thus, all previous motors are replaced by the rated power (0.32 kW/50 Hz) or (0.365 kW/60 Hz)

- Bifrequency ratings are omitted (separate versions for 50 Hz or 60 Hz)

- Resulting geometry changes are defined in Technical Information TI 71706

› Statement Ecodesign Directive 2009/125/EC (pdf)

› Technical Information TI 71706 (pdf)

Not included in the scope of the directive are fan less drives (TENV design) and motors with rated powers < 0.12 kW. This pumps will not be changed in motor power and geometric dimensions.

If you have any questions, please don't hesitate to contact us.

Your BRINKMANN PUMPS team

2022

12.08.2022

The AMB takes off – We are live!

We would like to invite you to visit us at the AMB 2022, the International Exhibition for Metalworking, in Stuttgart, Germany, from Sept. 13 - 17, 2022.

Don't miss our TEAM DIGITAL with the latest highlights on the digitalization of our products. Together, we would like to discuss with you the benefits of digital pumps and invite you to actively influence our latest development, which we will present to you as a preview.

Our team is looking forward to your visit at our booth 8D42 in hall 8.

01.03.2022

Press release

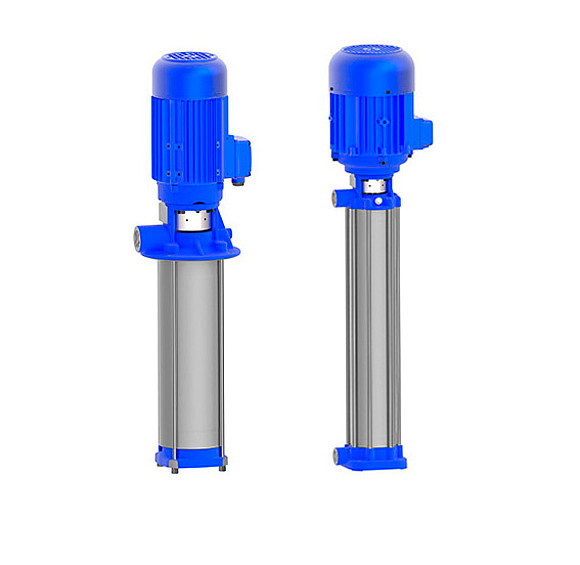

New immersion pumps for medium-pressure applications

Expansion of the STH series to include sizes 21 and 28

Powerful centrifugal pumps are used in machine tools and mechanical engineering. They are immersed in the fluid to pump, for example, cooling emulsions or coolants and cutting oils. BRINKMANN PUMPS is now expanding its range in this application area. The immersion pumps of the STH series can also be ordered in the large sizes 21 and 28 from March 2022.

With their closed impellers, the new pumps of the medium-pressure series impress with very good hydraulic efficiencies. The units cover flow rates of up to 1200 l/min and reach pressures of up to 20 bar. Another advantage is the fine characteristic curve graduation, which enables precise operating point design and also allows users to save energy. For special control tasks, it is also possible to use an add-on variable frequency drive matched to the pump characteristics.

Download press release and press picture:

Download zip file

2021

21.04.2021

Implementation of Ecodesign Directive 2009/125/EC, Regulation (EU) 2019/1781

With regard to the EU framework directive, all pumps with motor 0,12 kW ≤ 0,749 kW must be supplied according to the new motor efficiency classes, starting from 01.07.2021.

› Statement Ecodesign Directive 2009/125/EC (pdf)

For all affected pump, the performance date is available as a PDF file:

› Implementation of Ecodesign Directive 2009/125/EC (pdf)

At the end of June 2021, we will update the database of our web catalogues and CAD download database.

› Information of Ecodesign Regulations (EU) 2019/1781 (CAPIEL and CEMEP) (pdf)

2020

16.09.2020

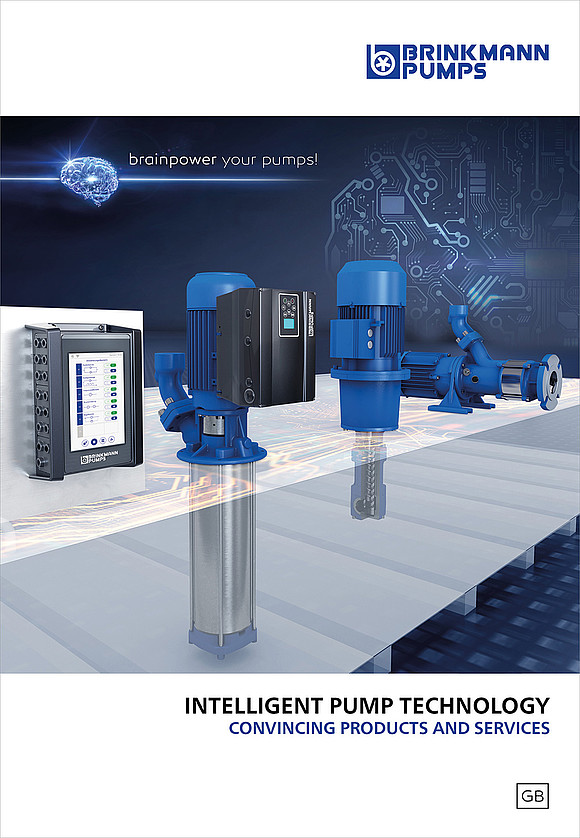

New Summary brochure

Intelligent Pump Technology – Convincing Products and Services

We would be pleased to send you your personal copy. Please send us a short message using our contact form (please see “Contact”) and fill in “Summary – Intelligent Pump Technology”.

Of course you can download the new brochure also in PDF format:

2019

11.03.2019

Press release

BRINKMANN PUMPS introduces innovative bplogic pump control system

Over the course of more than six decades, BRINKMANN PUMPEN K.H. Brinkmann GmbH & Co. KG (BRINKMANN PUMPS) has earned an unrivalled reputation for quality as a manufacturer of technologically sophisticated coolant pumps: The family business, which is headquartered in the town of Werdohl in the German region of Sauerland, employs more than 300 people worldwide and produces a broad range of equipment that is used in the machine tool, printing machine, plastics, and beverage industries.

And now, BRINKMANN PUMPS has a compelling new development that the company showcased for the first time ever last September at the AMB trade fair in Stuttgart: The intelligent bplogic pump control systembplogic. This system perfectly expands the company's existing line of coolant pumps to a new direction while at the same time representing a tremendous milestone in the journey towards digitalization. This innovative device is designed to be integrated between machine tools, pumps, filtration systems, and other components, and is able to adapt perfectly to system environments regardless of the variable frequency drive brands being used.

Find out more about bplogic here.

Download press release and press picture:

Download zip file

![[Translate to Italiano:] Stage Image](/fileadmin/user_upload/header_unternehmen_news_2200px.jpg)